Gold Extraction: Where Can You Extract Gold From?

Gold Extraction: Some everyday sources for a modern form of mining of precious metals

Approximately 85 percent of all the gold ever found is still being used today. Most of that can be found in electronics, catalytic converters and other man-made products like cellphones. All of these items have a shelf-life and when their time is up, precious metals can be recovered. Precious metal can also be gleaned from nature – in sand and seawater. The extraction of gold from all of these is possible through a variety of processes.

Electronics

Beyond outdated computers, several other electronics make use of the yellow metal. Televisions, radios, refrigerators and cellphones will all yield a fair amount of gold. Gold can be recovered from computer motherboards soaking an a cyanide solution to reach the gold contained within pins and sockets. To recover gold from motherboard chips, the chips must be burned and ground to a fine powder. Then one of many different methods may be employed including the aqua regia recovery process, pyrolysis and cupellation process. For the other electronics listed above, the first step is to remove the outer casing from the item. Then scrape any gold residue off with your screwdriver. Collect the gold residue.Sand

Panning is the most common method using of extracting gold from a material like sand. To make sure can recover the specks of gold, start with large mesh screens and work to smaller mesh sizes. Use a magnet to recover the fine black sand substance to be saved a dried later. Small bits of gold will be caught in them and when they are dry, you will be able to remove the ferrites and pan the material again. There is also drywasher that uses an electrostatic method to separate the two.Chemical extraction is not recommended for hobbyists. Acids, cyanide and mercury are all environmental and health hazards.Seawater

There is an estimated eight million tons of gold dissolved in the world’s oceans. And it is possible – though not practical – to extract that gold. After it was discovered by British chemist S. Sonstadt in 1872 that sewater contained gold, German chemist Fritz Haber, co-inventor of the Haber-Bosch process, spent most of his career trying to devise a method to separate the two to help pay Germany's post World War I debt. But the cost of evaporating then concentrating seawater would far outweigh the value of the gold obtained.

After it was discovered by British chemist S. Sonstadt in 1872 that sewater contained gold, German chemist Fritz Haber, co-inventor of the Haber-Bosch process, spent most of his career trying to devise a method to separate the two to help pay Germany's post World War I debt. But the cost of evaporating then concentrating seawater would far outweigh the value of the gold obtained. Ore

Minerals containing enough metal to be valuable are called ore. Precious metals are often extracted from ore through a combination of Given the chemicals used it is not recommended for hobbyists. Catalytic converters transform toxic emissions to less harmful ones through chemical reactions. Almost all present-day vehicles that use gas, have exhaust systems that include a catalytic converter. The catalysts used in these systems is usually platinum, palladium and rhodium - all of the platinum group metals. PGMs are in limited supply and and have a wide variety of industrial uses. Platinum is used in laboratory and dental equipment, electrical contacts and electrodes and jewelry. Palladium is used in fuel technology. In 2010, $3 billion worth of platinum, palladium and rhodium were recovered from discarded catalytic converters. Most of the recycled catalytic converters found today come from cars built more than a decade ago. The recoverable amounts of palladium, platinum and rhodium in each can range from one to two grams for a small vehicle to 12-15 grams for a big truck in the United States. The recovery value ranges from $25 to a few hundred dollars per vehicle. If you are looking to invest in proper gold coins to buy, or bullion, then you have come to the right place: International Precious Metals is a renown online coin dealer with nearly 20 years of experience, serving the numismatic community with trust as well as great prices.

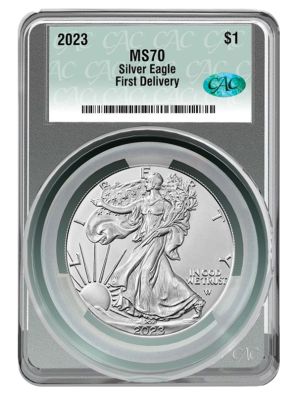

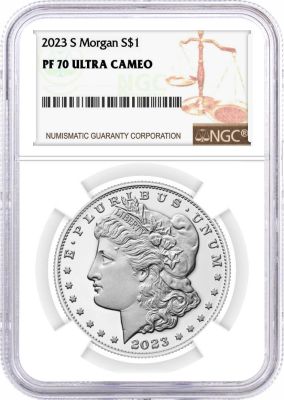

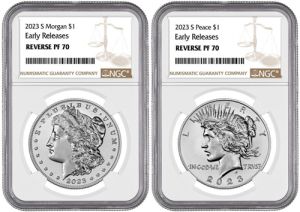

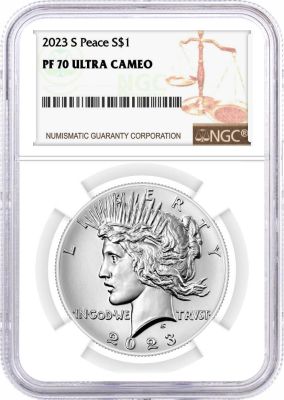

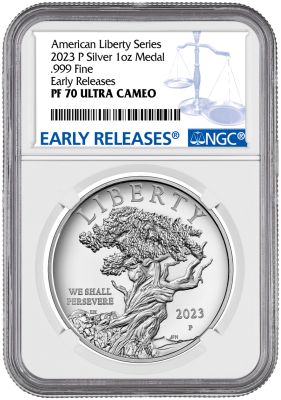

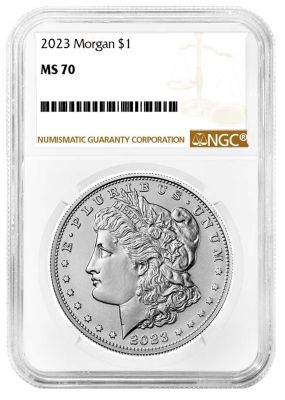

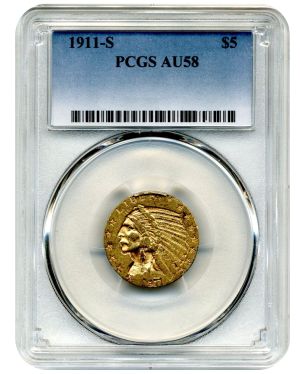

In 2010, $3 billion worth of platinum, palladium and rhodium were recovered from discarded catalytic converters. Most of the recycled catalytic converters found today come from cars built more than a decade ago. The recoverable amounts of palladium, platinum and rhodium in each can range from one to two grams for a small vehicle to 12-15 grams for a big truck in the United States. The recovery value ranges from $25 to a few hundred dollars per vehicle. If you are looking to invest in proper gold coins to buy, or bullion, then you have come to the right place: International Precious Metals is a renown online coin dealer with nearly 20 years of experience, serving the numismatic community with trust as well as great prices.